Note: Free Shipping for Australia only

YAY! You have found our premium quality synthetic paper - a much loved sticker paper by many full-time and DIY sticker makers.

Choose from a variety of quantity options, including 10, 50, 150, 250, and 500 sheets. Larger quantities are available via email and pre-order.

Size: 210mm x 297mm (A4)

Our synthetic paper is approximately 150gsm, with an 85gsm matte synthetic top layer and a 70gsm white paper liner. The top layer is a bright white, providing the perfect canvas for your sticker printing needs. The backing sheet is a slightly darker white, mildly transparent, and free from any watermarks.

Cutting: Tested on a Silhouette Cameo and Cricut machines for kiss cutting and die cutting. Top tip: If using overlay - increase your settings to do an extra 'pass'.

Storing your paper: Keep your sticker paper in a cool, dry place out of any direct sunlight. Australian humidity can create bending and bowing in your sticker paper if not stored correctly.

The synthetic matte texture of our paper is buttery smooth to the touch, making it a pleasure to write on with all types of pens and pencils.

Suitable for use with inkjet printers only.

PRINTING TIPS:

-

Some printers have additional settings available when you install their driver. Make sure you have correctly installed the printers driver / software from their website for full settings.

-

We recommend using Semi-Gloss or Matte Paper settings when selecting the Media Type.

-

Adjust any default settings that mention Fast or Draft modes. Instead select High or Fine.

Every printer brand and model has its own unique settings and quirks. These are just some handy tips that we have picked up along the way.

MAKING WEATHERPROOF STICKERS AT HOME:

While our sticker paper is water-resistant (we have had the same sticker in our dishwasher for 2+ years to test this) it is not the only element required in making a fully weatherproof sticker. Here is the ultimate run-down on making GOOD weatherproof stickers at home:

- The waterproof / weatherproof nature of your sticker making is determined by the ink in your printer and the process in which you make your stickers.

- To make fully weatherproof stickers, your printers needs to be using specialised ink that is fade resistant (especially in the Australian sun).

- Most consumer / home printers use dye ink and water based inks that are high in vibrancy but are not fade resistant.

- Pigment inks are fade resistant but more expensive and typically don't have the same vibrancy that you would find in an affordable home dye ink / water based inkjet printer. Often these types of inks (in full colour) are found in commercial printers and not affordable consumer / home printers.

- The next step in creating a weatherproof sticker is lamination. Cold laminate is applied to the high-quality vinyl stickers that you find at stores or made by a commercial manufacturer. This protects the design from hand oils, scratches and other elements.

- For home printing and cutting, you can purchase A4 sheets of cold laminate and with a bit of a patience (and a squeegee) you can add some extra protection to your stickers (and cool glittery overlays). This will also contribute greatly to the rate in which is fades. Stash World has these available sometimes (but it's not something we keep in stock regularly).

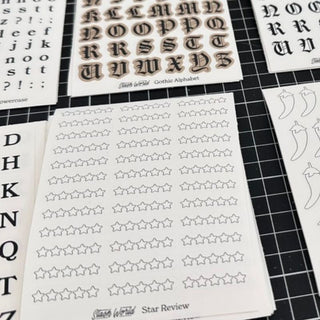

So with all of that being said - our sticker paper is best suited for DIY labels and planner stickers that require a high-quality finish. To increase the durability of your stickers, consider using an additional laminate overlay after printing and before cutting.

If you are wanting a large quantity of 1000+ sheets, please get in contact with us via email to arrange a custom price.

Order now and have your paper shipped from our Brisbane, Australia sticker workshop. Free local pick-up also available.

Note: Free Shipping for Australia only

YAY! You have found our premium quality synthetic paper - a much loved sticker paper by many full-time and DIY sticker makers.

Choose from a variety of quantity options, including 10, 50, 150, 250, and 500 sheets. Larger quantities are available via email and pre-order.

Size: 210mm x 297mm (A4)

Our synthetic paper is approximately 150gsm, with an 85gsm matte synthetic top layer and a 70gsm white paper liner. The top layer is a bright white, providing the perfect canvas for your sticker printing needs. The backing sheet is a slightly darker white, mildly transparent, and free from any watermarks.

Cutting: Tested on a Silhouette Cameo and Cricut machines for kiss cutting and die cutting. Top tip: If using overlay - increase your settings to do an extra 'pass'.

Storing your paper: Keep your sticker paper in a cool, dry place out of any direct sunlight. Australian humidity can create bending and bowing in your sticker paper if not stored correctly.

The synthetic matte texture of our paper is buttery smooth to the touch, making it a pleasure to write on with all types of pens and pencils.

Suitable for use with inkjet printers only.

PRINTING TIPS:

-

Some printers have additional settings available when you install their driver. Make sure you have correctly installed the printers driver / software from their website for full settings.

-

We recommend using Semi-Gloss or Matte Paper settings when selecting the Media Type.

-

Adjust any default settings that mention Fast or Draft modes. Instead select High or Fine.

Every printer brand and model has its own unique settings and quirks. These are just some handy tips that we have picked up along the way.

MAKING WEATHERPROOF STICKERS AT HOME:

While our sticker paper is water-resistant (we have had the same sticker in our dishwasher for 2+ years to test this) it is not the only element required in making a fully weatherproof sticker. Here is the ultimate run-down on making GOOD weatherproof stickers at home:

- The waterproof / weatherproof nature of your sticker making is determined by the ink in your printer and the process in which you make your stickers.

- To make fully weatherproof stickers, your printers needs to be using specialised ink that is fade resistant (especially in the Australian sun).

- Most consumer / home printers use dye ink and water based inks that are high in vibrancy but are not fade resistant.

- Pigment inks are fade resistant but more expensive and typically don't have the same vibrancy that you would find in an affordable home dye ink / water based inkjet printer. Often these types of inks (in full colour) are found in commercial printers and not affordable consumer / home printers.

- The next step in creating a weatherproof sticker is lamination. Cold laminate is applied to the high-quality vinyl stickers that you find at stores or made by a commercial manufacturer. This protects the design from hand oils, scratches and other elements.

- For home printing and cutting, you can purchase A4 sheets of cold laminate and with a bit of a patience (and a squeegee) you can add some extra protection to your stickers (and cool glittery overlays). This will also contribute greatly to the rate in which is fades. Stash World has these available sometimes (but it's not something we keep in stock regularly).

So with all of that being said - our sticker paper is best suited for DIY labels and planner stickers that require a high-quality finish. To increase the durability of your stickers, consider using an additional laminate overlay after printing and before cutting.

If you are wanting a large quantity of 1000+ sheets, please get in contact with us via email to arrange a custom price.

Order now and have your paper shipped from our Brisbane, Australia sticker workshop. Free local pick-up also available.

Customer Love

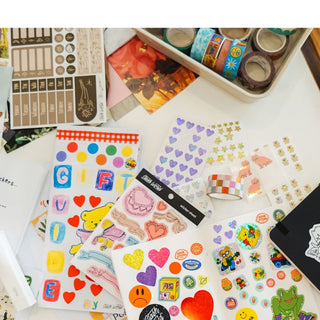

"One of my all time favourite stationery stores with a wonderful selection of stickers, pins and accessories. Orders arrive quickly and well packed. I always look forward to when my happy mail order arrives from Stash World!"

- Elizabeth

our Mission

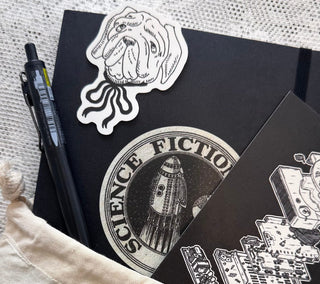

Bringing you the mindless and creative joy of stickers...

Through thoughtful production, curation and collaborations with independent makers and artists.